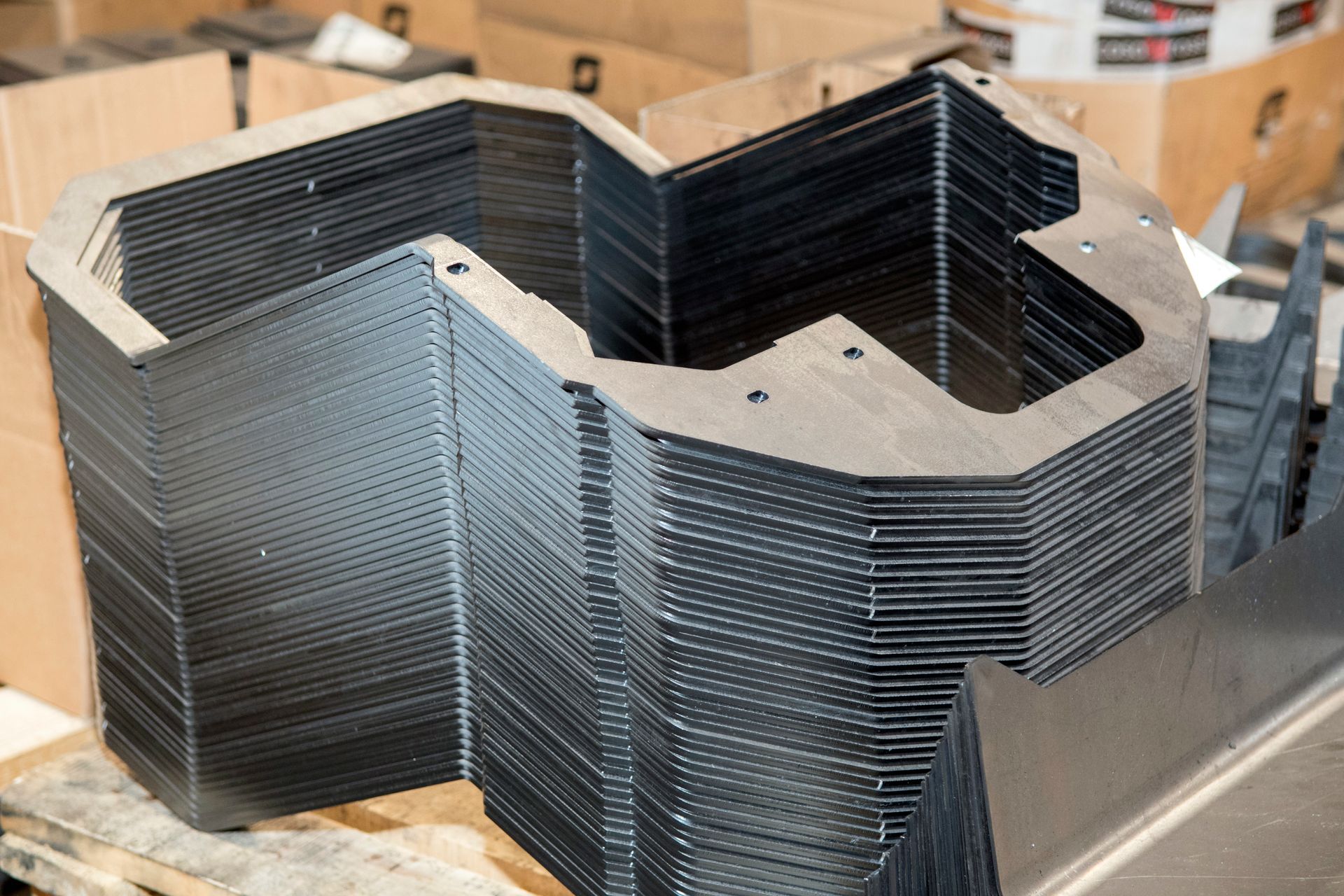

Piegatura lamiere

Molti i servizi messi a disposizione da Ense s.r.l. per la propria clientela, tra i quali la piegatura di lamiere. Una tecnica di lavorazione che comporta una deformazione permanente attraverso un’azione di flessione.

I metalli presentano al loro interno una “fibra neutra” che, senza allungarsi o contrarsi, può essere deformata. La buona riuscita dell’operazione è interamente basata sulle differenti proprietà dei metalli selezionati. Questi devono infatti essere sufficientemente plastici, così da non generare delle rotture nei pressi della piega.

Per compiti di questo genere è necessario affidarsi a gruppi di grande esperienza, come Ense s.r.l., in grado di determinare, ed eventualmente correggere, il ritorno elastico. Ense mette al servizio del cliente qualità, una robusta struttura e soluzioni elettroniche d’avanguardia, come una performante piegatrice per garantire alte prestazioni

PIEGATRICI

ENSE SRL dispone di 5 piegatrici di ultima generazione capaci di piegare una vasta gamma di materiali. Con la massima lunghezza di piega di 6.6 m e 1000 t di forza con carico concentrato di 400t/m, le nostre piegatrici

garantiscono la massima precisione e uniformità nella piegatura, permettendo la realizzazione di componenti complessi con elevata qualità. Grazie alla tecnologia avanzata possiamo effettuare piegature personalizzate in base alle specifiche esigenze dei clienti, ottimizzando i processi produttivi e riducendo i tempi di consegna.

Specifiche tecniche

Lunghezza piena: 6200 mm

Incavo: 1000 mm

Tonnellate: 1000 nominali

Carico concentrato: 500 Ton/metro

Macchinari

- N° 1 CMP 50 Ton x 1250 mm

- N° 1 SCHIAVI 125 Ton x 1250 mm

- N° 1 CBC 300 Ton x 3000 mm

- N° 1 SCHIAVI 400 Ton x 5000 mm

Piegatura in aria

Sfruttando un punzone superiore è possibile ottenere la piegatura in aria, pressando la lamiera in una matrice inferiore a V. Sono tre in totale i punti di contatto tra la superficie da piegare e la macchina, due sulla matrice e uno sul punzone. Saranno poi i tecnici a determinare l’angolo di piega, che deriva dalla profondità alla quale scende il punzone.

Un procedimento che tiene conto dell’over-bending, un fenomeno che consiste letteralmente in una piega maggiore del necessario, al fine di compensare il ritorno elastico, così da ottenere l’angolo selezionato. Il comparto tecnico di Ense s.r.l. saprà sempre optare per la scelta migliore, con la piegatura in aria che offre svariati vantaggi, dalla minor forza necessaria alla possibile piegatura di lamiere di grosso spessore.

Coniatura e Appiattimento

Per operare la coniatura è necessario l’utilizzo di un punzone, che proceda a pressare del tutto la lamiera, raggiungendo il fondo cavo della matrice inferiore. È fondamentale che matrice e punzone presentino lo stesso angolo di inclinazione. In questo modo infatti si riesce ad eliminare del tutto il ritorno elastico. Si opta per questo sistema principalmente per piegature di angoli a 90°, con lamiera sottile. Un’opzione che garantisce precisione, oltre all’ottenimento di angoli inferiori rispetto alla piega in aria.

Sono due le fasi dell’appiattimento. La prima risulta essere una pre-piega, tra 26 e 35 gradi (con piegatura in aria). La seconda è una schiacciatura parziale o totale della lamiera. In questo modo si ottengono rigidità, protezione dei bordi ed eliminazione di spigoli liberi.

Nuovo macchinario per la piegatura: Trubend 5320

Piegatrice di maggior successo a livello mondiale. Dalla programmazione all’attrezzaggio, fino alla piegatura vera e propria non ha rivali in twemrine di produttività:

- silenziosa e veloce

- l’ondemand servo drive funziona in modo energeticamente efficiente, rapido e silenzioso

- sistemi di misurazione angoli: con i sistemi di misurazione angoli della famiglia ACB, già il primo pezzo esce perfetto

- flessibile grazie al registro posteriore a 6 assi che garantisce la massima libertà di applicazione

CARATTERISTICHE:

- forza di pressione: 3200 kN

- lunghezza di pigatura 4420 mm

- passaggio libero del montante 3680 mm

- apertura utile 1615 mm

- sbraccio 420 mm

- interfaccia utente Touchpoint TruBend

- velocità asse y fase di lavoro (opzione): 25 mm/s

Taglio

Taglio lamiere e metalli di diverse dimensioni e spessori. Taglio ad acqua, taglio laser, taglio al plasma e ossitaglio.

Sbavatura

Operazione di finitura che permette di raggiungere la massima perfezione e i pezzi trattati sono pronti all’uso.

Contattaci

Domande? Siamo qui per aiutarti. Inviaci un messaggio per essere ricontattato.