Taglio Laser

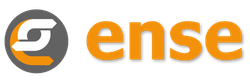

Il taglio laser consente un taglio ad alta velocità su lamiere di diversi spessori

Tagli precisi e veloci

Ense, azienda specializzata nel taglio e piegatura delle lamiere a 360° con le tecnologie per il taglio più innovative, offre i suoi servizi alle aziende dislocate in tutto il nord Italia.

L’azienda è all’avanguardia anche nel settore del taglio laser, grazie a macchinari di ultima generazione che consentono un taglio ad alta velocità sia su lamiere sottili che su spessori maggiori, come l’acciaio da 25 mm.

Il taglio laser è una tecnica di lavorazione che può essere applicata a molte tipologie di materiali e di forme. Tra i vantaggi del taglio laser vi è infatti la possibilità di tagliare anche forme geometriche di piccole dimensioni con la massima precisione. Inoltre, rispetto al taglio meccanico, il taglio laser è più netto e ha un grado di contaminazione pressoché nullo.

TAGLIO LASER con LAVORAZIONI MECCANICHE

ENSE SRL dispone di quattro macchine per il taglio laser, due a tecnologia CO2 ottimizzata a 6 kW e due a fibra ottica.

Grazie alla tecnologia avanzata e ad una misura utile di 3050x12000 mm, le nostre macchine sono in grado di tagliare spessori da 0,5 mm fino a 25 mm ottimizzando una potenza di taglio massima di 12KW.

Con l'ausilio di 2 teste in contemporanea si ottimizzano significativamente i tempi di lavorazione ed i costi.

Le nostre macchine laser sono dotate di funzione di

taglio "Bevel"

e attrezzate per eseguire lavorazioni meccaniche come

foratura

(max diam. 14mm) e

filettatura

(filetto minimo M4 e massimo M12).

Campo di lavoro

Asse X: 6000 mm

Asse Y: 2000 mm

Asse Z: 115 mm

Peso massimo del pezzo: 2800 Kg

Spessore massimo

Acciaio da costruzione: 25 mm

Acciaio Inox: 25 mm

Alluminio: 15 mm

Massime velocità

Per assi paralleli: 200 m/min

Simultanea, ca: 300 m/min

Precisione

Min. percorso programmabile: 0,01 mm

Scostamento di posizione Pa: +/- 0,1

Max potenza garantita: 5000 - 6000 W

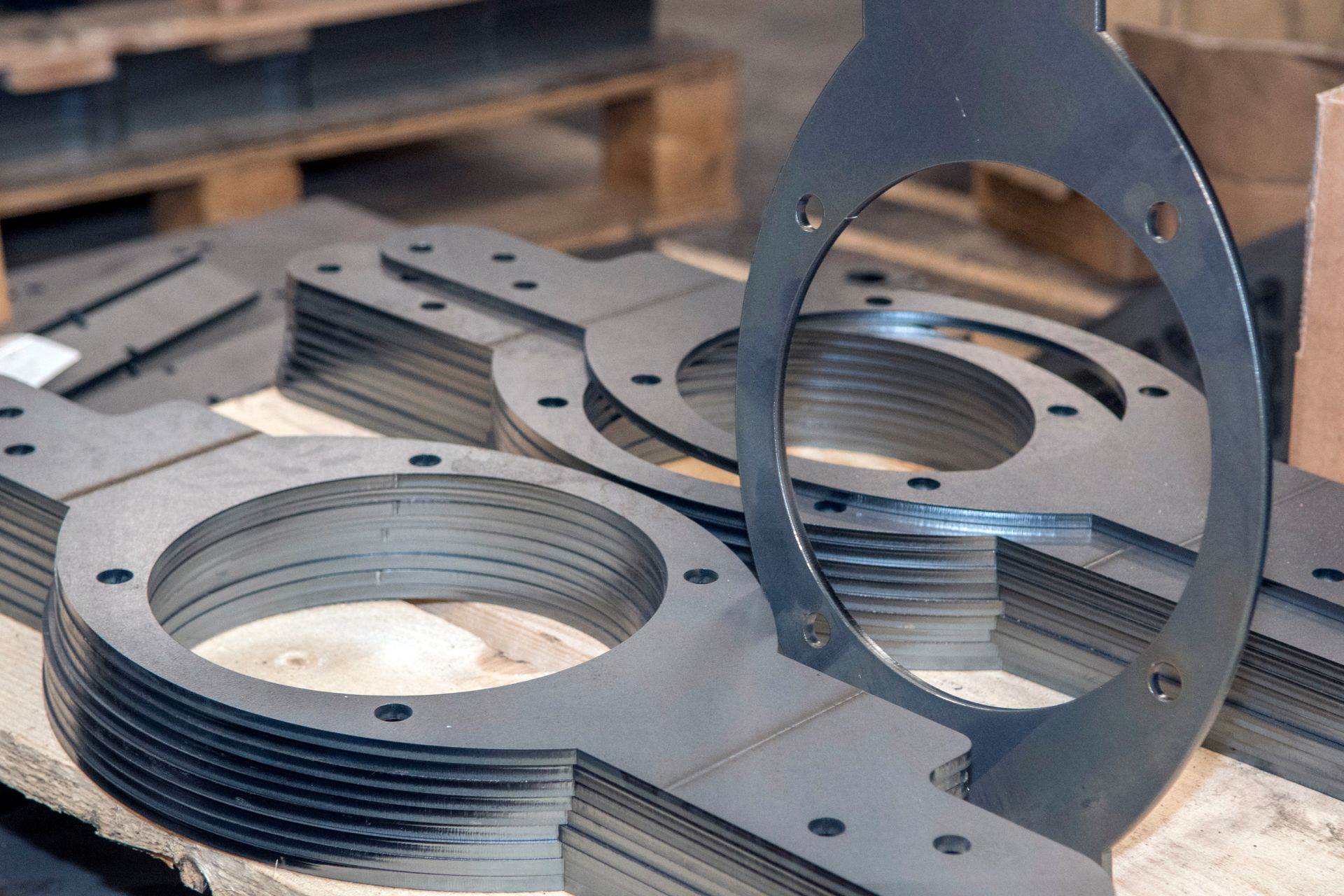

Taglio laser di diversi materiali

Le macchine utilizzate per il taglio laser sono costituite dalla testa di taglio, da un sistema di assi o un braccio robotizzato, da una struttura schermata che serve a proteggere gli operatori da eventuali incidenti e dal controllo numerico che consente di controllare tutta la lavorazione.

Le macchine per il taglio laser possono essere utilizzate sia singolarmente che all’interno di linee composte da magazzini automatici, sistemi di carico e di scarico o in linee combinate.

Ense ha a disposizione macchinari in grado di tagliare l’alluminio fino a 15 mm di spessore e l’acciaio inox e l’acciaio da costruzione fino a 25 mm, con una potenza massima garantita di 5000 – 6000 W.

Piegatura

Eseguiamo lavorazioni a freddo di piegatura delle lamiere di diversi spessori e materiali.

Sbavatura

Operazione di finitura che permette di raggiungere la massima perfezione e i pezzi trattati sono pronti all’uso.

Contattaci

Domande? Siamo qui per aiutarti. Inviaci un messaggio per essere ricontattato.